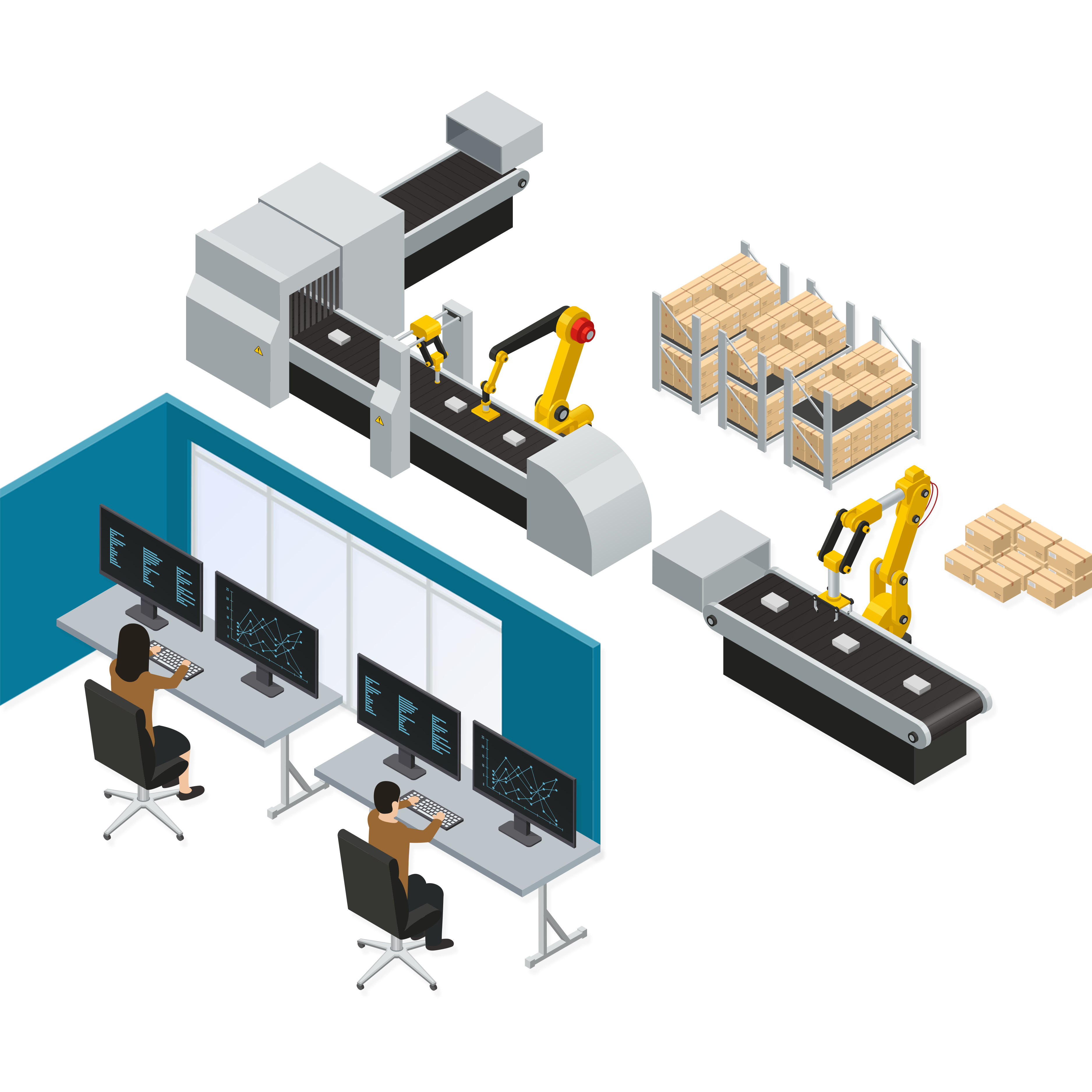

Production planning is a crucial aspect of managing any manufacturing business, as it helps to remove complexity and improve efficiency for sustainable growth. Most of the Manufacturers who implement effective production planning software can optimize their machine scheduling, reduce downtime, and maximize their production capacity, resulting in increased profitability.

Effective machine optimization and capacity planning are crucial

for manufacturers to maximize their production efficiency and

output.

By implementing a comprehensive production planning system,

manufacturers can better manage their production operations,

from planning and scheduling to materials and resource manage-

ment. Like, Zenscale can forecast demand and plan production

accordingly, ensuring optimal machine performance and capacity

utilization.

The system can also automate production scheduling based on

machine availability, ensuring that production is always running at

maximum capacity. Manufacturers can boost productivity, reduce

costs, and stay ahead of the competition.

Manufacturers can use production planning tools, such as ERP

systems, to manage their production operations, plan and sched-

ule for production, and track machine performance.

For example, an ERP system like Zenscale's Production Planning

module offers features such as capacity planning, scheduling, and

material requirements planning (MRP), enabling manufacturers to

optimize their machine utilization, plan for materials, and schedule

production to meet customer demand.

With such tools, manufacturers can achieve operational excel-

lence and gain a competitive edge in their industry.

Plan material requirements for each production will help to avoid stock outs. Here you can get material requirement planning reports in a single dashboard with scalable solutions to manage manufacturing processes with MRP Software. This ensures that you have the right materials on hand at the right time, avoiding production delays.

Our production ERP software provides a streamline system for managing all aspects of production, from work orders and inventory management to machine scheduling and quality control. This ensures that all production activities meet the needs of all sized manufacturers.

With Purchase order management software, optimize inventory levels, production bottlenecks and gain visibility to track all processes timely. Automate procurement process to create purchase orders quickly and set alerts and notifications and avoid stock outs.

Plan and Monitor all level flows at one place such as Multi Level BOM of materials, Costing, Procurement, Planning, Process Routing, Raw material to finished goods, scheduling, material requirement planning, sale & purchase with Zenscale.

Through production erp software, easily manage work orders, job orders, sale and purchase orders easily in a quick without any hassle. Get a one stop solution to manage all your production operations.

The testimonials feature lets you collect kudos from customers and clients and display them on your Site in different ways to add credibility and a professional feel.

The production planning software has transformed our manufacturing operations. We used to struggle with inefficient workforce and processes, but now we can easily track and manage our workflow. The software has increased our efficiency and reduced our lead times, which has been a game-changer for our business."

- Sharman Leathers" We have been using the production planning software for over a year now and it has been a great investment for our company. The software is easy to use and has helped us improve our capacity planning, which has resulted in increased productivity and profitability. We highly recommend this software to any manufacturer looking to streamline their operations."

-Papertex Specialty Chemicals Pvt Ltd, Punjab." As a 30crore company, I was hesitant to invest in production planning software, but after seeing the benefits first-hand, we can't imagine running our business without it. The software has helped us optimize our resources and manage our inventory more effectively, which has reduced our costs and improved our customer satisfaction."

-Bell Hydromatics ." As a large manufacturer, I was struggling to keep up with demand and manage our production schedules and also keep up with sampling. The production planning software has helped us stay on top of our workflow and ensure that we are meeting our deadlines. The software is user-friendly and has allowed us to compete with larger companies in our industry."

-Shingora Limited" The production planning software has been a game-changer for our business. We are now able to forecast demand more accurately and plan our production schedules accordingly. The software has also helped us identify bottlenecks in our operations and make data-driven decisions to improve our efficiency. We highly recommend this software to any manufacturer looking to stay ahead of the curve."

- Rajesh Kumar